After bending the small piece at the grid-line, an alteration had to be made. In the original design plans, this bend should be a 45 degree bend from the inside. When we attempted to bend it this far, the grid started cracking (most likely due to the amount of holes in the grid and the thinness of the sheet metal). To compensate, we bent it to a 60 degree angle from the inside, as far as it would bend without snapping. Although the fixture may look different than the original design, it should have no effect on the light emission of the LEDs. Below is a picture of the 60 degree angle (measured counter-clockwise)

This is the Drexel Engineering 103 blog for group 068-06. The goal of this lab is to create a LED fixture that can be implemented into a dementia ward at St. Francis Country House to help the health of the patients there. We are working with Group 068-05 to achieve this goal of creating a working prototype. Our group is primarily focusing on the manufacturing of the physical light fixture while the other group is working on programming the LEDs to simulate daylight.

Tuesday, May 14, 2013

Bending and Alteration #2

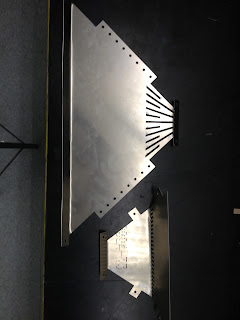

We are currently in the process of bending each of the pieces! Below is a picture of an large upper piece bent at the top and bottom, and a small lower piece bent at the top tab and at the grid-line

After bending the small piece at the grid-line, an alteration had to be made. In the original design plans, this bend should be a 45 degree bend from the inside. When we attempted to bend it this far, the grid started cracking (most likely due to the amount of holes in the grid and the thinness of the sheet metal). To compensate, we bent it to a 60 degree angle from the inside, as far as it would bend without snapping. Although the fixture may look different than the original design, it should have no effect on the light emission of the LEDs. Below is a picture of the 60 degree angle (measured counter-clockwise)

After bending the small piece at the grid-line, an alteration had to be made. In the original design plans, this bend should be a 45 degree bend from the inside. When we attempted to bend it this far, the grid started cracking (most likely due to the amount of holes in the grid and the thinness of the sheet metal). To compensate, we bent it to a 60 degree angle from the inside, as far as it would bend without snapping. Although the fixture may look different than the original design, it should have no effect on the light emission of the LEDs. Below is a picture of the 60 degree angle (measured counter-clockwise)

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment